About Us

Our Approach - "No Cutting Corners"

1. Take It Seriously

The commitment to No Cutting Corners is the foundation of delivering critical air conditioning function and reliability.

The team at Critical Air has built a culture over many years of providing a team serious and taking pride in critical function, reliability and:-

- Maintaining an end-user focus. Over 90% of our combined project and maintenance turnover is direct for end-users. This enables us to understand you and your business so that it's almost like we're part of your team.

- Continuity through all phases, Installation and Maintenance. We have full continuity with the vast majority of our customer's sites providing unbroken accountability.

- Commitment to True-Cost, Standards, Communication, People, Efficiency and Improvement.

- Achieving customer results that reinforce the culture.

- We have a customer retention rate comparable to industry best.

2. Deliver the best True-Cost outcome

When function and reliability are critical, all cost elements need to work together for minimum total True Cost

Under-designing and under-maintaining can lead to major operational, downtime and energy cost problems and high True Cost. However, unchecked over-design and over-maintaining is pure waste, and can also lead to excessive True Cost. We are always pursuing the optimum balance.How we can help:

- Most importantly – by having the mindset and commitment to work with you, to understand all aspects of your situation, and maximise your system’s financial performance

- Energy cost minimisation

- Designing and implementing a preventative maintenance program that encapsulates all the elements of a high quality maintenance program

- Fixed cost comprehensive maintenance options to control risk and budget fluctuations

- An overriding policy that ALL proposals, large and small, must be assessed to our clients’ True Cost benefit

3. Commit to Standards

To achieve consistent function and reliability, we set Operating Standards in five areas:

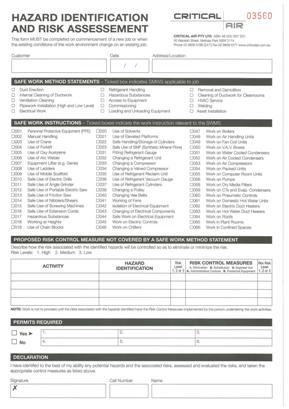

- Safety / Compliance

- Timing

- Effectiveness

- Documentation

- Presentation

Any consistently achieved Standard must be backed up by well-resolved and formalised processes, performance measurement and ongoing improvement. Some examples are:

| 1. Safety / Compliance | |||

|

Our OH&S system is Trades Monitor Assessed and Certified to AS4801 certification THIS MEANS – Peace of Mind when we are working on your site

|

|

|

|

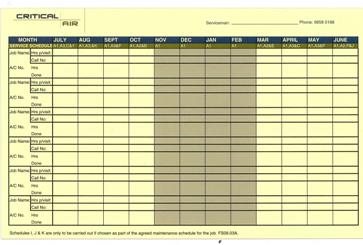

| 2. Timing | |

|

Critical preventative maintenance tasks are performed within specified upper and lower time interval limits. This particularly applies to condition monitoring intervals that must fit within the window between detectable failure and actual failure. |

|

|

THIS MEANS – Minimal in-service failures |

|

|

Breakdown response time is guaranteed 24/7 within the agreed time frame (98% 2015–16). |

|

|

THIS MEANS – Back on-line ASAP |

|

| 3. Effectiveness | |

|

Standardised (and continually evaluated) procedures are used to detect lead indicators of failure. Field Audits are carried out on all our Technicians to ensure that what has been agreed to in our contract with you is delivered in full ensuring you receive value for money. |

|

|

THIS MEANS – Minimal in-service failures |

|

|

Preventative maintenance hours on site are guaranteed. PM Schedules are logged and tracked monthly to ensure correct timing. |

|

|

THIS MEANS – No short-cuts on preventative maintenance and you receive value for money |

|

|

Standardised root cause analysis methodology is applied to all component failures by all service personnel. |

|

|

THIS MEANS – Quicker return to service and less follow-on failures |

|

|

Maintenance standards as dictated by manufacturers and or DA19 apply to all items. |

|

|

THIS MEANS – You know that it’s done once and done well |

|

|

4. Documentation |

|

|

Site maintenance log books are always in place and up to date. THIS MEANS – Ready identification of repeat problems. Problems fixed quickly if original technician unavailable |

|

|

ALL failures are logged and data based for analysis. THIS MEANS – You can be confident that we are operating on facts, not assumptions |

|

|

5. Presentation |

|

|

Maintenance and installation standards both include system appearance and site cleanliness criteria. |

|

|

THIS MEANS – When the site looks smart, you look smart |

|

|

Critical Air personnel adhere to personal appearance and vehicle standards. |

|

|

THIS MEANS – When we look professional, you look professional. |

|

4. Report and Communicate

|

The best technical efforts in the world can be undermined by poor communication. Our approach here is:

|

5. Train and retain the right People

|

Critical Air has a five-decade history of training, since its inception in 1961 as McNeall Air Conditioning. Some of our people-practices that really make a difference are:

|

6. Drive Efficiency

Efficiency always matters – even for critical systems, and we are as committed as you.

- “Electronic Pen” data recording of site maintenance activities, avoiding the “paper chase”, and allowing better retrieval of information.

- Keeping up with Technology changes and Innovation. Constant improvement to our ERP System (Pronto). Use of Internet based portals for improved customer interaction.

- Ongoing process improvement to focus on cost-benefit and minimise non-value-add.

- Comprehensive fixed-cost maintenance options are available, one of the greatest benefits of which is to save on your admin costs.

7. Always Improve

At Critical Air, we are focused on measurement and improvement:

- All issues and difficulties raised by customers result in a formal process review and definite feedback to the customer.

- Customer surveys and post-job reviews are routine.

- Field audits of jobs & personnel are routinely carried out